Digital management upgrade and Enhance production safety and efficiency

Smart safety helmets integrated with various sensors and intelligent technologies, provide innovative solutions to enhance production safety and efficiency across multiple industries. Below are the key application sectors and their functional highlights:

1. Construction Industry

Widely used in construction sites, smart helmets employ GPS and Beidou to monitor personnel real-time location, and worker status (e.g., helmet compliance wearing and removal notice, falls) in real time, effectively reducing accident risks and improving management efficiency.

2. Power & Energy Sector

In scenarios like power line inspections and high-altitude work, smart helmets feature proximity voltage warnings (detecting 110V-380kV) and live video streaming, enabling remote expert guidance to prevent electrical hazards and boost maintenance efficiency. Detachable design smart helmet camera can also be deployed in tower climbing and base station inspections.

3. Oil,Gas, Mining & Chemical Industry

For hazardous environments, gas detection or other sensor module can be installed to these smart helmet, used to monitor and detect toxic gas leaks, temperature, humidity, and noise, triggering alarms for anomalies. Their SOS emergency system and precise positioning (GPS/BeiDou) enable rapid rescue responses.

4. Transportation,Railway Maintenance and Tunnel construction

In remote repair and operation, smart helmets’ fall detection and emergency alerts address incidents promptly, while voice communication and track replay optimize team coordination and work documentation.

Key Features Summary

**Enhance working efficiency

1.Remote viewing

HD camera supports high-definition picture capturing and 1080P video transmission. Laser lights can assist in camera positioning, photography, and video recording. Equipped with OIS (Optical Image Stabilization) anti-shake camera can ensure images clearer and videos more stable. Click the photo/video recording button when required and can save inside the helmet camera system memory or transmitted back to platform in real-tim through 4G/WIFI. When On site maintenance personnel encountered difficulties while repairing equipment, the backend engineer can see the on-site returned image via 4G and Wi-fi and provide remote assistance.

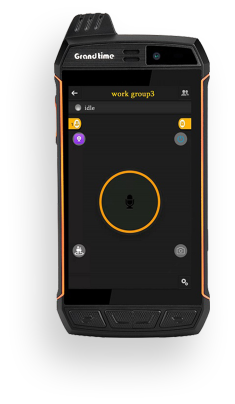

2.Real-time communication

Support real-time audio and video calls with the back-end platform through 4G or WiFi. The back-end can also broadcast important notifications to all personnel through voice messages. When on-site personnel encounter danger, they can press SOS button reporting to back-end platform and seek help.

3.Real-time tracking the location

Support GPS/Beidou positioning, real-time control personnel position.

Support electronic fence to prevent personnel from entering dangerous areas or leaving designated work areas.

Support trajectory playback, truly grasp daily work routes

**Ensure worker safety

- Smart sensors for real-time alarm to personnel and platform

Support for hat removal alarm to prevent wearers from taking off their smart safety helmets Support silent alarm and fall down alarm, allowing staff to receive rescue in time. Proximity voltage sensors can prevent personnel from electrical hazards.

Customizable solutions:

- Support adding external sensors for detecting toxic gases

- Support AI intelligent voice assistant to free hands for processing all the functions

- Can integrate AI algorithms to check the completion of work. Identifying tasks, tracking progress, inspecting quality, and checking process compliance through AI algorithms can improve efficiency, enhance quality, and strengthen safety.